Information sourced from:Internet Published on:2022-04-01

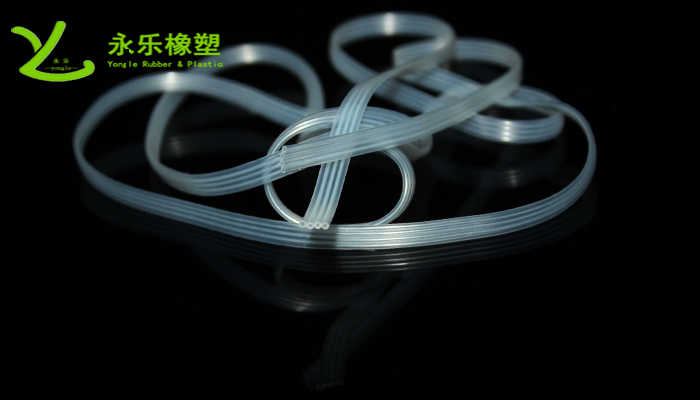

The delivery hose for Baijiu without plasticizer is a high-performance environment-friendly hose, which is suitable for the delivery of food, oil, water chemical liquids under general working pressure and the surface decoration of various instruments, especially for working at extremely low temperatures. Superior and good appearance texture, soft and gentle touch, soft and bendable; Anti slip, earthquake resistant, impact resistant, and excellent elasticity; Excellent tensile resistance, good tensile strength, and a fracture elongation rate of over 10 times.

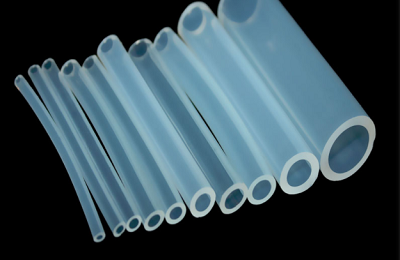

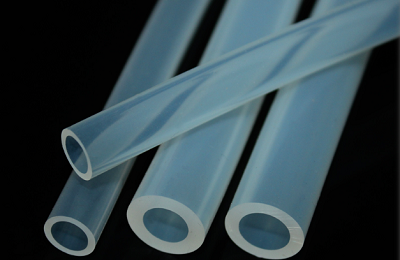

Food grade silicone tubing is made from imported silicone raw materials, using scientific production processes and intermittent methods to produce raw rubber. It is designed for the high tear resistance and transparency of gas-phase adhesives, the ultra-high and lower hardness of mixed adhesives, and functional mixed adhesives. This product has a wide range of adaptability

Silicone tubes are safe and environmentally friendly, with good comprehensive performance, and have been applied in many industries. In our daily life, high-temperature resistant silicone tubes are one of the most commonly used silicone tubes. High temperature resistant silicone tubes: non-toxic and odorless, cold and high temperature resistant, soft, elastic, resistant to twisting and deformation, not cracking, and have a long service life

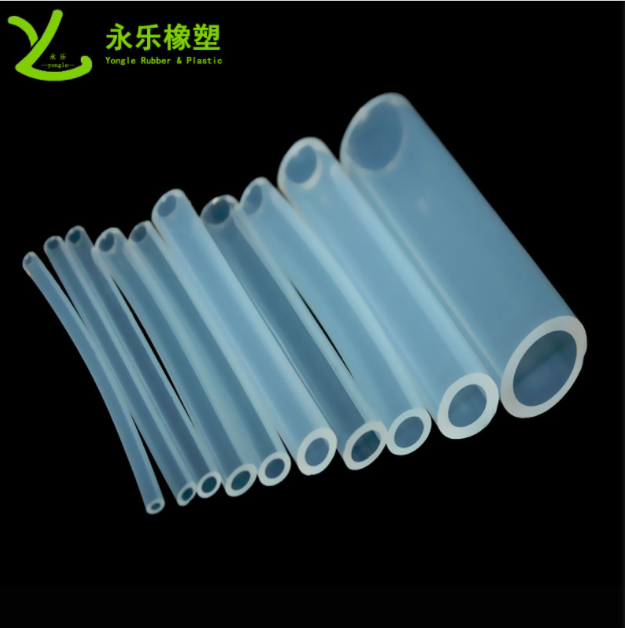

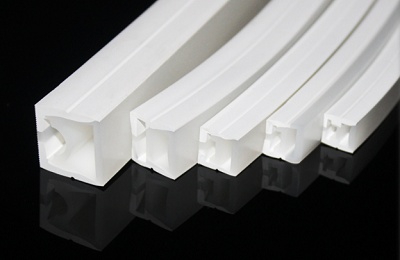

Silicone rubber tubes are carriers for the flow and encapsulation of liquids, gases, and other materials. In the industry, silicone rubber tubes can be divided into "extruded tubes" and "special-shaped tubes". They are widely used in modern industry, national defense industry, and daily necessities. Silicone tubes are made by adding silicone rubber raw rubber to a double roll rubber refining machine or a closed kneading machine, gradually adding white carbon black and other additives to repeatedly refine them evenly

Silicone ringUnsealing may be caused by installation issues, incorrect installation direction of sealing components, or foreign objects or dust entering the sealing chamber during installation, leading to leakage. Improper assembly causes damage to the sealing components, resulting in leakage. Scratches on the surface of the sealing rod cause leakage. The piston rod is not concentric, causing leakage due to biased load.