Information sourced from:Internet Published on:2024-02-19

Medical silicone tubing, as the name suggests, is a product that can be applied freely in the medical industry, as third-party platforms such as hospitals and institutions need to provide consistent elastic materials for every patient and person in need. And it can be applied in various environments, such as medical devices, respiratory circuits, medical catheters, etc. Because medical silicone tubing can pass biocompatibility reports and comply with multiple tests such as LFGB and FDA.

1、 Density: Foamed silicone tubing and any foam product are important properties. Currently, the mainstream density in the market is between 0.3 and 1.0, and the conventional non foaming density is stably controlled at 1.2, which is one of the connections.

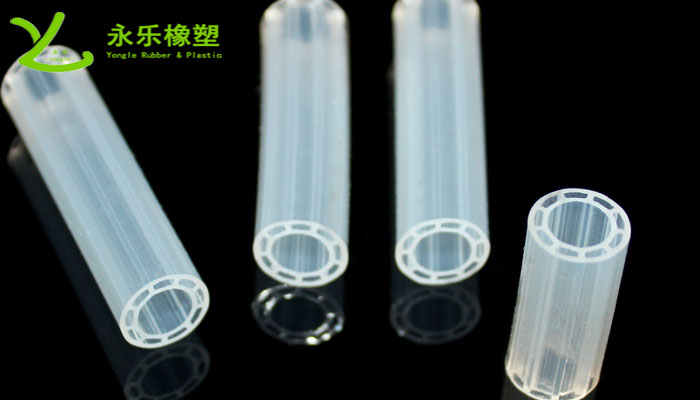

In the current market, woven silicone tubing can be divided into several categories, including extruded tubing and special-shaped tubing. The woven silicone tube needs to be refined repeatedly during the refining process. At present, it has been widely used worldwide. Mainly used for modern and rapidly developing industries, defense technology, and some of our daily necessities.

The function, mechanism, and influencing factors of silicone gaskets are to prevent the leakage of the sealed medium, and the forms of leakage can be divided into interface leakage and permeation leakage. The causes of interface leakage are usually due to the relaxation of the pressure between the sealing surfaces, aging, deformation, corrosion, wear or burning of the sealing surfaces, and mechanical vibration during operation. Penetration leakage is related to the material type, manufacturing method, properties of the sealed medium, as well as factors such as working pressure and temperature of the silicone sealing gasket.

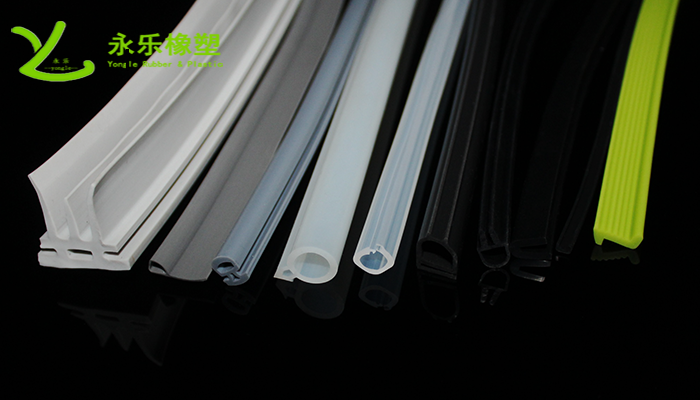

It is necessary to learn how to properly maintain the silicone strip, because only after learning how to maintain it can we ensure that its use effect is more awesome. Especially when using the silicone strip of cars, if you do not learn how to maintain it, it is easy to cause abnormalities. Then, how should you maintain it better.